Introducing Engineered Remote Monitoring

Simply monitoring a Coldroom ambient temperature can be misleading. With this older style or ‘budget’ solution the worst case scenario is a cascade of equipment failure, disguised by an apparently ’acceptable’ ambient room temperature – behind this can be a myriad of unseen failure such as frozen fans, frozen pipes, loss of coolant via leakage and in larger installations even complete condenser compressor failure.

A Condenser failure where a Coldroom has multiple units can lead to the remaining units running continuously to take up the slack…never powering down as intended and running outside of duty cycle – potentially causing damage – therefore causing excessive power consumption ( currently only noticed in the utility bill at a later date ) …When the problem finally shows as an ambient temperature warning an engineer has to then travel to site to start to diagnose the whole installation and carry out potentially multiple repairs. This is where stock and business is jeopardised.

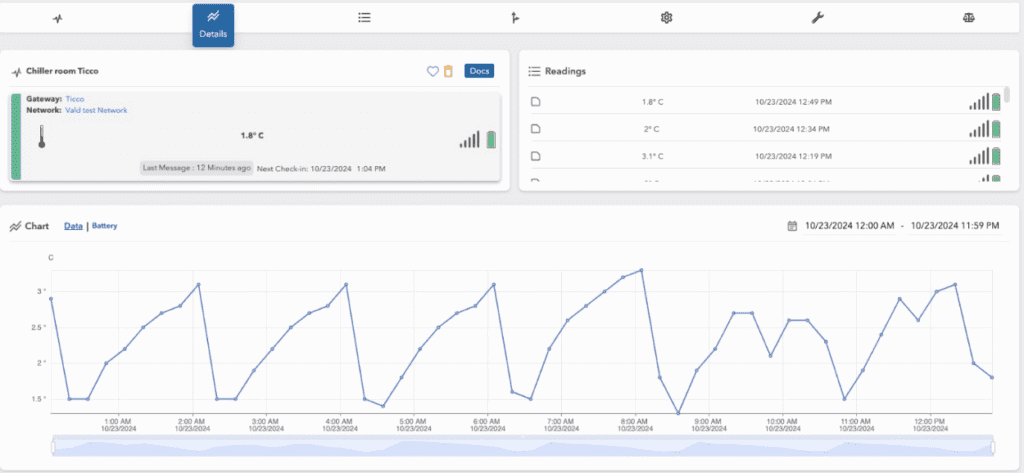

Our solution monitors systems pipework pressure and itemised temperature – this provides an early warning of imminent failure. We are made aware 24/4 and the act to ensure you avoid potential damage to your vital equipment – helping its longevity by avoiding running damage.

We can also monitor power consumption – this can also provide an early warning action to investigate before a fault becomes critical or even noticed.

We do not need to access your I.T. network. Monitoring can be linked to onsite maintenance SLA’s.You will of course be provided access a suite of temperature reports for your own reporting/auditing purposes.

Systems can be bought in 1 and 3 three year contracts ( or you can self monitor )

Call us to discuss how this can best work for you and /or arrange a demonstration.